Crossfield Products is a manufacturer of a variety of construction coatings and fluid-applied flooring materials. While they have been growing for the past 80 years, their processes had not kept up with the growth. Despite being one of the oldest companies in the industry, competition was catching up and was taking Crossfield’s business away. Crossfield knew it was time to change and get back in the lead.

The Situation

Change was going to be difficult at Crossfield as most of the employees were set in their own ways – some of the employees at the company had been working for the company for over 30 years. In the beginning even the President of the company was a little skeptical about a successful Lean Transformation of his company.

How

Result

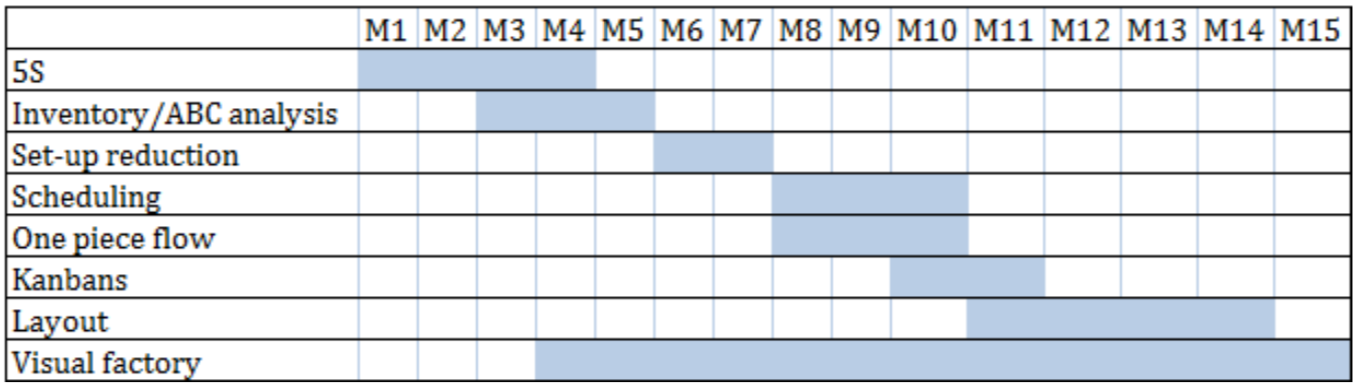

Using change management techniques and involving people at all levels of the company, we were able to bring about the much needed change. The biggest success was that all the employees started to think in a Lean way. After the initial resistance, all employees were on board. Using a multi-phase approach, and using various Lean tools and methodologies, we were able to:

–Save the company more than $1 million per year

–Reduce finished goods inventory by 78%, and space requirements by 47%

–Improve lead time by 25%

–Eliminate the need for an external warehouse

–Develop a new production scheduling methodology

–Create a workload balancing system

–Increase productivity by using 5S and visual factory concepts

–Reduce raw material cost by consolidating and standardizing packaging sizes

Pacific Propeller International (PPI), a subsidiary of Precision Aerospace Products, provides propeller repair service and overhaul services for domestic and international airlines and the military. Earlier this year the company was having trouble keeping up with demand, and its three major contracts – representing 80% of their revenue – were at risk of being compromised for failure to deliver propellers on time.

Pacific Propeller International (PPI), a subsidiary of Precision Aerospace Products, provides propeller repair service and overhaul services for domestic and international airlines and the military. Earlier this year the company was having trouble keeping up with demand, and its three major contracts – representing 80% of their revenue – were at risk of being compromised for failure to deliver propellers on time.

With three major contracts on the line, Pacific Propeller International needed our help to overhaul their processes—quickly. PPI had five weeks to create an aggressive plan for improvement (phase 1).

Background

PPI’s three contracts include repair and return, blade manufacturing, and propeller overhaul. The company was struggling to keep up with their turnaround (lead time) target of 90 days, which had crept up to 208 days. With the fear that they were about to lose their valuable contracts and recognizing the need to reduce lead time, PPI’s President reached out to us, and asked for guidance. During the 15 minute call, WE listened to the client and explained the benefits of a process review. They were on board out of the gate.

The timing wasn’t ideal, as PPI had a very short response time – five short weeks – to get their process in order. We worked out an arrangement that if PPI’s President was willing to commit himself and his team to the effort, we would make ourselves available, including evenings and weekends.

How

Extensive and detailed process mapping was conducted. Key process were identified and mapped. During the mapping sessions, most of the waste was discovered and identified, and a plan to eliminate the waste and non-value adding activities was developed, and subsequently executed.

Teaming Up With the Client

PPI’s President agreed to work with us, and was dedicated to the success of the process. He pulled his weight and worked many late nights and weekends to make sure he got the desired results. Among other things we were able to increase productivity by 24% and decrease production time by 21%. At a high level meeting in Washington, DC, within a month, the improvements were very well received by PPI’s client, and they were very excited about real progress and the implementation of Lean practices at PPI. Using Lean, PPI wants to double their output within two years.